Force sensitivity

Ultra-sensitiveness to contact forces thanks to in-house designed, industry-leading torque sensors in all 7 axes. Their excellent resolution, accuracy and repeatability enable dynamic sensing of the environment and exceed the performance of most purpose-built force sensors. The robot can apply slight forces to perform tasks such as joining, inserting and screwing. Continuous and accurate fine tuning of forces is also a requirement for applications such as contour tracking, polishing and grinding.

Precision

Elegant combination of industrial-grade revolutionary sensing and industrial-grade position control. Additionally to the force sensing capabilities, the robot also features the characteristics of a classic rigid industrial robot with a pose repeatability of < +/- 0.1 mm (ISO 9283) mm and negligible path deviation even at high velocities. This enables precise, robust and fast execution of manufacturing processes.

Agility

Within its workspace, it can reach and operate far-off (855 mm) as well as very close to its own base, and the geometry of the 7 axes allows for complex poses to reach difficult spaces, allowing execution of processes even in confined environments.

| Axes | 7 |

| Reach | 855 mm |

| Workspace coverage | 94.5% |

| Max. end effector speed | 2 m/s |

| Payload | 3 kg |

Interaction

Adjustable guiding modes compensate gravity and friction to reduce the perceived weight up to a factor of 60, ensuring smooth and elegant interaction between human and machine. And the Pilot interface is conveniently at hand on the robot Arm, allowing for remote control of the user interface. Besides, our sophisticated sensors, control algorithms and internal model allow prompt detection and reaction upon unwanted collisions within milliseconds.

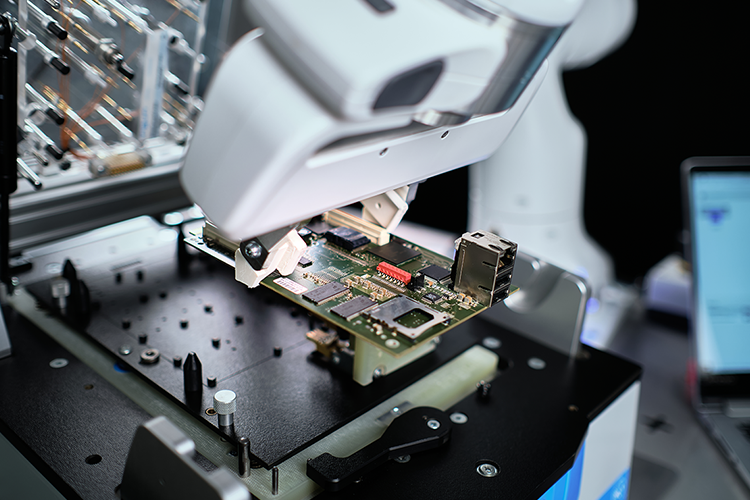

Components

Franka Robotics robots incorporate highest mechatronic integration. It is equipped with more than a hundred sensors of various types, including in-house designed, industry-leading torque sensors in all 7 axes, as well as high resolution position sensors, brushless DC motors, strain wave gears and cross roller bearings.

| Absolute position encoders resolution | 14 bit |

| Joint electronics communication bus | 1 kHz |

| Motor | Brushless DC |

| Strain wave gears | Zero backlash |

| Cross roller bearings | Highly rigid |

| Torque sensors resolution | 13 bit |

| Production in Bavaria, Germany | Highly automated |

Next steps:

Applications

A wide offer range that lowers your barrier to entry into the world of automation.

%20resized.png?width=230&height=61&name=Franka_Robotics_Logo-65mm_Black%20(1)%20resized.png)